CRITICAL APPLICATIONS LEAVE NO ROOM FOR COMPROMISE

Food and beverage production is considered one of the most critical compressed air applications. Health hazards, costly recalls and perishable goods make for a complicated field to set a reliable system up. Get guidance on how to tackle this challenge!

Compressed air, or pneumatics, plays a major role in many areas of the food industry. It is used for transporting ingredients, processing doughs and drinks and packaging finished products. Even if the compressed air does not come into direct contact with the product, it is often used to operate machines and systems, to transport containers and for other ancillary activities.

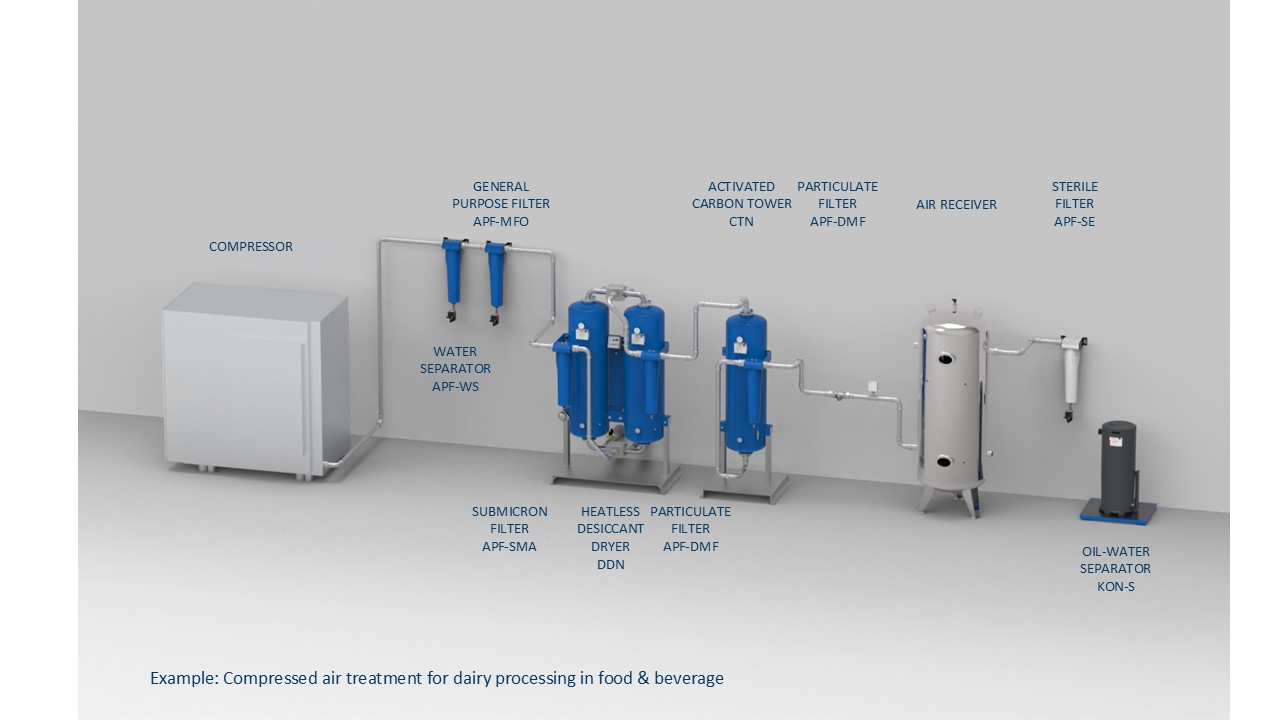

Compressed air systems can usually be divided into 3 broad areas: compression, treatment and distribution. In many facilities, the compression and treatment (filter and dryer) are located in the so-called compressor room. The distribution extends over the entire production area and is usually realized by widely branched pipe networks.

POSSIBLE RISKS FROM COMPRESSED AIR

Due to the direct or indirect contact of compressed air with the final product, compressed air is considered a critical control point in HACCP where product safety can be compromised.

As the compressed air passes through many different units and travels long distances before it reaches the point of use, there are many potential sources of contamination: In the compressor due to mechanical abrasion, at leaking valves or screw connections, in filters at irregularly maintained filter elements…

QUANTIFICATION OF COMPRESSED AIR QUALITY

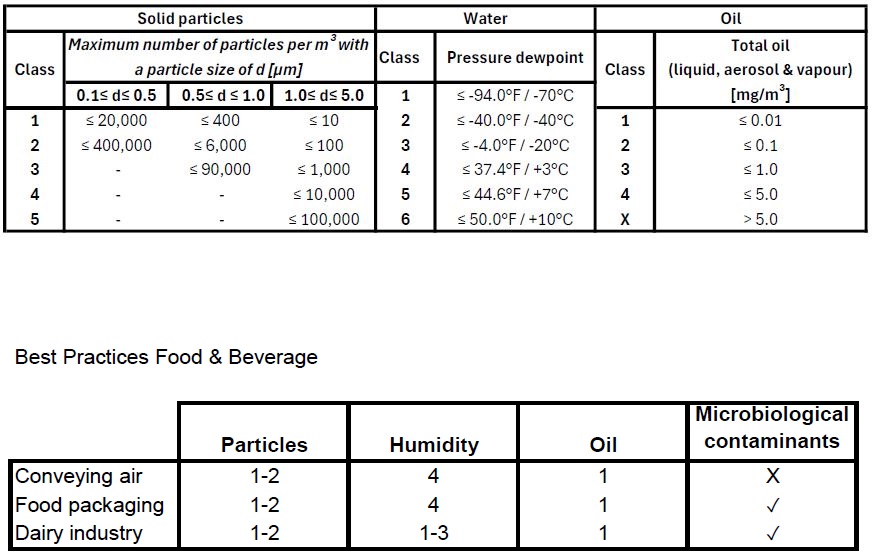

ISO 8573 was created to make the compressed air quality in the network objectively measurable and controllable. This standard lists the most important contaminants in compressed air systems and divides them into quality classes: Particles, water, oil.

In addition, the sub-standard ISO 8573-7:2003 defines a test method for determining viable microbiological contamination. This makes it possible to determine or rule out the presence of bacteria and fungi in the air.

MAINTAINING THE COMPRESSED AIR QUALITY

The quality of compressed air in food production must be ensured by several measures in accordance with GMP:

1. selection of appropriate systems and components to achieve the quality requirements

2. appropriate upkeep (maintenance) and review of the system and the associated quality requirements

3. documentation of processes, maintenance, calibrations and test procedures for compliance with regulatory requirements

The first step in introducing a resilient compressed air system in food production is selecting the appropriate equipment to achieve the required quality. The core of every compressed air treatment system is the right dryer. To achieve a humidity class 4 or lower a refrigerated dryer is usally sufficient. If class 3 or higher is demanded, a desiccant dryer is the go-to solution.

Residual oil content should be contained to a minimum in any food application, therefore an activated carbon tower should be used to adsorb any oil drawn into the air stream.

If the air has direct contact with the food product, a filtration system optimized to filter out microbiological contaminants like bacteria or fungi should be employed. Those contaminants behave like particles in the compressed air stream and can therefore be removed effectively by a filtration element. It is important to establish a procedure to sterilize the filter element frequently in order to neutralize and remove the biological particles caught in the filtration media.